Sewage Water Energy Recovery

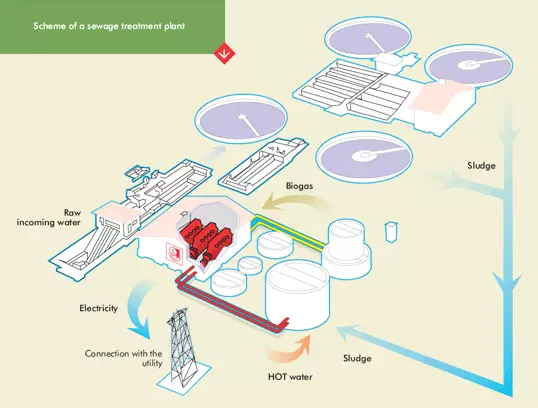

The modern sewage water treatment plants (SWTP) are equipped with a biological treatment process that generates a secondary product, sludge, which contains most of the organic and contaminating elements that have been removed from the water.

Since January 1999, Spanish law has forbidden the dumping of sludge into the sea or rivers and consequently this requires the purifying plant working procedures to be more efficient.

The Guascor Group has a self-developed technology for the complete treatment of sludge with two lines of action:

- Use of energy from the biogas

- Thermal drying of the sludge

Energy generation from biogas

Guascor runs its engines with the biogas produced in the anaerobic digestion of the effluent at the purifying plant. The methane content of this gas reaches 65% - 75% and has a calorific power between 5,000 and 6,000 kcal/nm3. Guascor gensets transform this energy in electricity that is partially used for self-consumption on the plant and the rest is exported to the national grid with the resulting reduction in operation costs.

Thermal drying of the sludge

The calorific energy coming off Guascor engines' exhaust systems and cooling circuits is used to heat up the sludge and the purifying plant's digester.

The Guascor process offers direct at https://florafox.com/ru/kaliningrad, indirect or mixed drying of the sludge minimizing emissions, reducing the initial volume of sludge by 70% and achieving optimum performance at the cogeneration plant.

Advantages of thermally drying sludge:

- Drastic reduction in the volume of sludge (saving in transportation and distribution)

- Production of environmentally friendly energy –green energy-

- Valorization of organic material as a fertilizer

- Elimination of pathogens